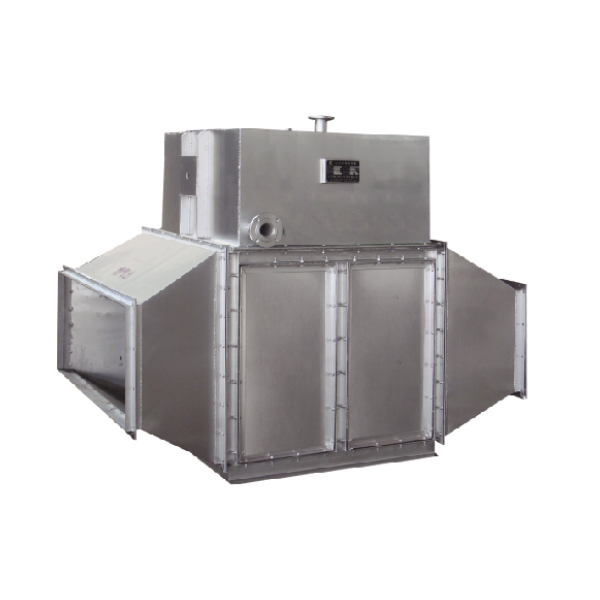

Waste heat recovery system

flue heat exchanger

We're here to help

Easy ways to get the answers you need.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

Coke oven gas in the combustion chamber, in which exhaust fumes, through regenerative chamber after the sensible heat of checker brick recycling through small flue, flue gas exchange shutter, points, total flue and chimney discharged into the atmosphere. Before these waste gas into the chimney, the temperature is about 270-300 ℃, after flue and chimney emission of waste gas can not effectively use contains large amounts of waste heat, waste of the available heat energy. Along with the national policy for energy conservation and emissions reduction and monitoring strength increase and enterprise need to improve the competitiveness, such as the heat is used for waste heat boiler, the recycling equipment, not only to reasonable development and utilization of coke oven flue gas waste heat resources effectively, and can solve the coking production required for steam, realize the energy saving and improve the economic benefit of enterprises. By coking flue gas waste heat recovery system on the part of the flue gas waste heat recovery, and generate 15 tons/hour, 0.8 MPa low pressure saturated steam for production use, greatly reduces the production cost, and energy conservation and environmental protection effect.

Get Price And Support

Please leave your telephone number or mobile phone nubmer for emergency contact, in case we can not reach you by mail.

anterior:flue gas heat exchanger

+Newsmore

- 01 Apr,2016Assembling evaporator to plastic body with Pakistan client. Professional fin evaporator manufacturer Shanghai Shenglin,

- 01 Apr,2016Australian client visited us last Saturday

- 06 Jan,2016Packaged rooftop units finished for Nigeria client

- 03 Sep,2015Free Cooling Precision AC Finished for Russian Client

- 21 Jan,2015CE Certification for Heat Pump